Extrusion evolved

EIS is the only application that enables recipe development before dies reach the press, featuring isothermal extrusion capabilities in the intermediate version and comprehensive thermal management in the full version.

Features

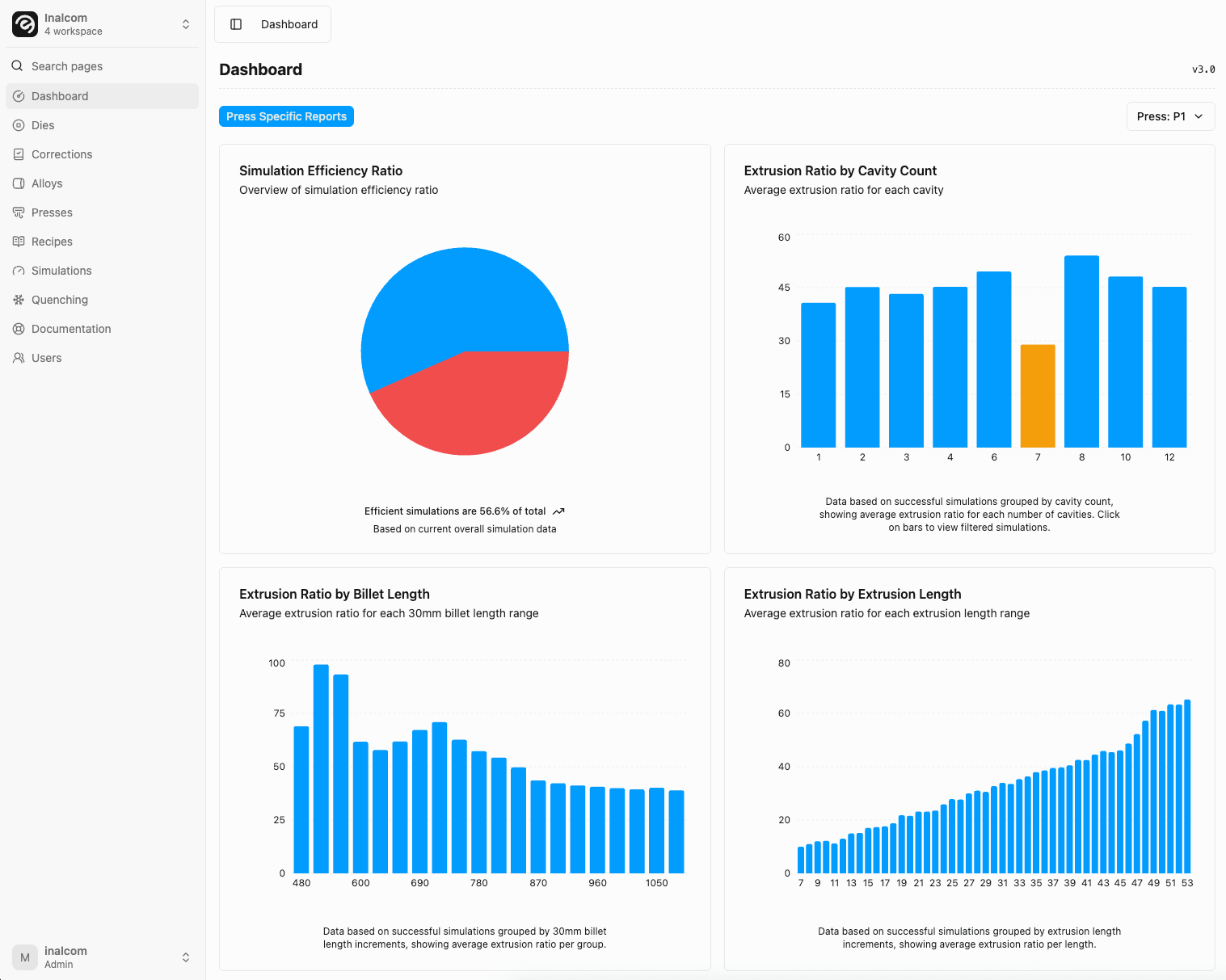

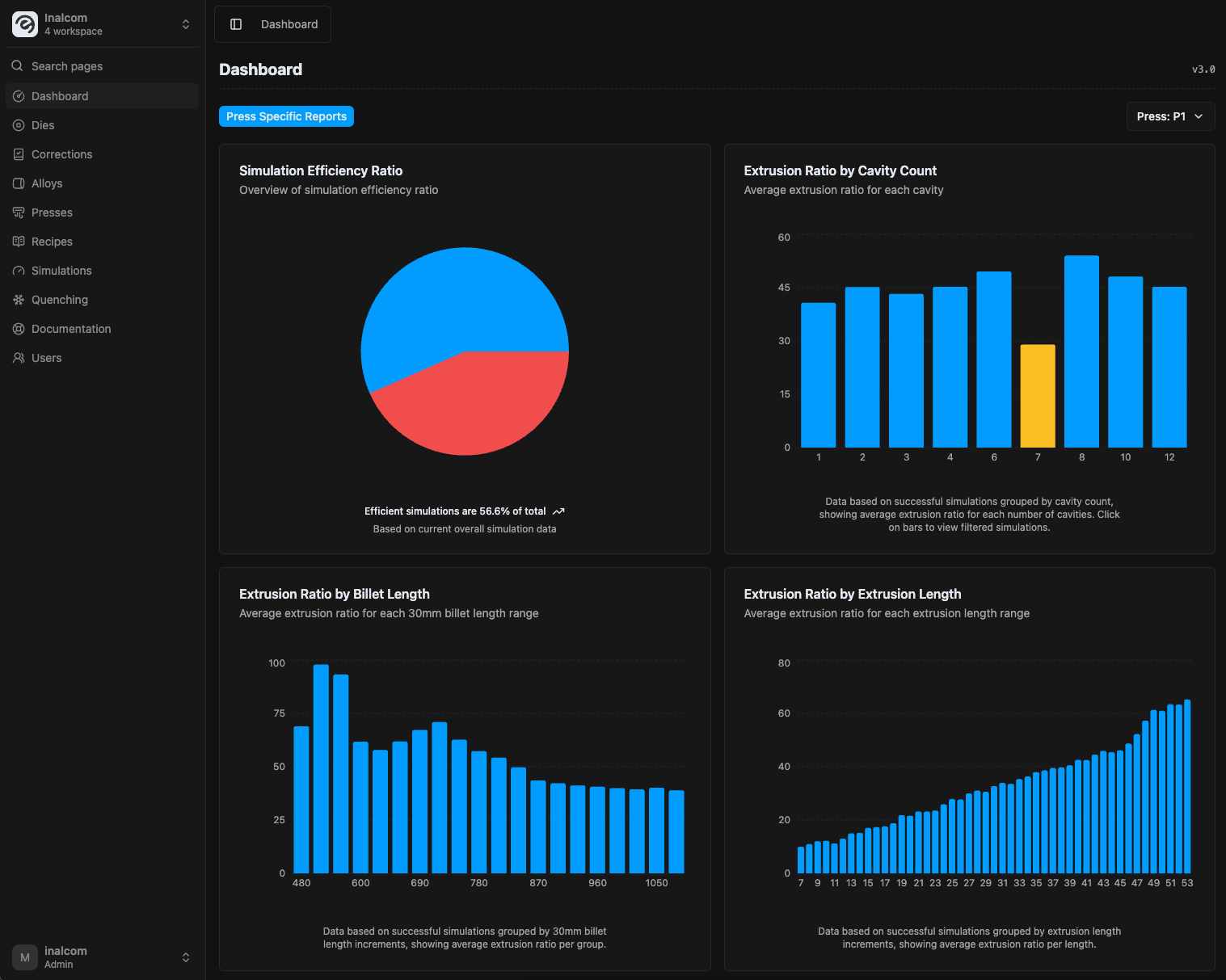

Performance Metrics

Press productivity calculation and analysis to optimize extrusion performance and efficiency.

Speed

Ram speed and puller (product) speed calculation for optimal extrusion process control.

Scrap

Press scrap calculation to minimize waste and improve material utilization in extrusion processes.

Cost

Production cost calculation to analyze and optimize manufacturing expenses and profitability.

Temperatures

Billet, container, and die temperature calculation for optimal thermal management.

Quenching

Press quenching and temperature control calculation for proper heat treatment processes.

Billets

Billet length, quantity, and unit per time calculation for efficient material planning.

Coring and Welding

Coring and welding scrap calculation to minimize waste in hollow profile production.

Stretching

Stretching value and force calculation to ensure proper material deformation and product quality.

Corrections

Die correction logs and die correction maintenance monitoring for quality assurance.

Quality

Assurance of dimensional accuracy, surface quality and mechanical properties.

Reports

Performance metrics, trends, and analytical reports for comprehensive process analysis.

Contact us

Get in Touch

Ready to optimize your manufacturing processes? Contact us today to discuss your specific needs and learn how our expertise can help drive your business forward.

Address

APDO 510 43800 VALLS (TARRAGONA) SPAIN

Phone

+34670098209

sales.inalco@gmail.com

extrusionsim@gmail.com

Quick Response

We typically respond to all inquiries within 24 hours. For urgent matters, please call us directly.